Table of Contents

Disposable surgical gowns are the unsung heroes in the battle against healthcare-associated infections, which affect 1 in 31 hospital patients daily.(GE Healthcare) These essential garments, made from high-quality non-woven materials like polypropylene, provide a crucial barrier against pathogens in medical settings. Their single-use nature eliminates cross-contamination risks and offers cost-effectiveness by reducing laundry expenses. Disposable gowns combine strength, durability, and breathability, ensuring both protection and comfort during lengthy procedures. As a critical line of defense in operating rooms, they allow healthcare professionals to focus on patient care without worrying about infection spread. By maintaining high hygiene standards, disposable surgical gowns play a vital role in enhancing safety and efficiency in medical practices. Understanding their importance and composition is key for healthcare facilities aiming to optimize their safety protocols and invest wisely in protective equipment.

Importance of Disposable Surgical Gowns

Purpose and Use

Disposable surgical gowns are crucial in protecting both patients and healthcare workers. Imagine a busy operating room. Without these gowns, the risk of infection skyrockets. They act as a barrier, preventing bacteria and other pathogens from transferring between the patient and medical staff. This protection is vital, especially during surgeries where exposure to bodily fluids is high. Think of them as shields, ensuring a sterile environment and reducing the chance of cross-contamination. (Prevent & Protect)

Regulations and Standards

Disposable surgical gowns are subject to rigorous international standards and regulations to ensure adequate protection in medical settings.

In the United States, the FDA regulates them as Class II medical devices, while the ANSI/AAMI PB70 standard establishes a four-level classification system based on liquid barrier performance. The ASTM F2407 standard outlines testing methods for various gown properties.

In the European Union, the EN 13795 standard specifies requirements and test methods, classifying gowns as “Standard Performance” or “High Performance”. (Comparison Table)

Internationally, ISO 16603:2004 focuses on resistance against blood-borne pathogens. These standards collectively ensure that disposable surgical gowns meet necessary safety, durability, and performance criteria for medical use, with manufacturers required to comply with relevant regulations for their target markets.

Top Materials Used in Manufacturing Disposable Surgical Gowns

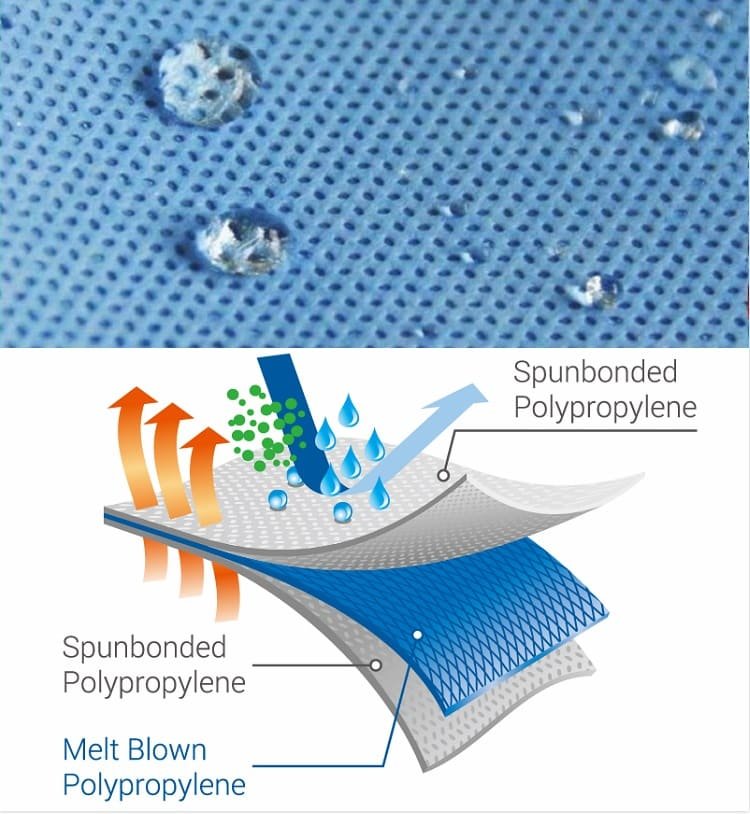

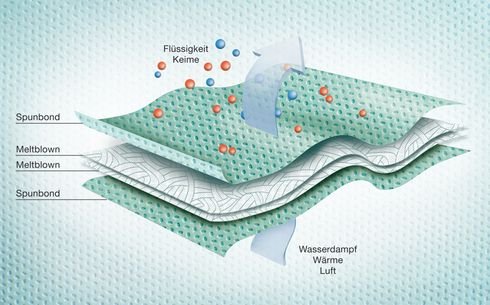

SMS (Spunbond-Meltblown-Spunbond) Fabric

The key to SMS fabric’s effectiveness lies in its structure. The spun-bond layers provide strength and durability, crucial for a gown’s protective function. Meanwhile, the melt-blown layer acts as a filter, blocking microorganisms and fluids, thus maintaining a sterile environment. This balance makes SMS an optimal choice for disposable surgical gowns, ensuring both safety and comfort for healthcare professionals.

SMMS (Spunbond Meltblown Meltblown Spunbond) Fabric

SMMS (Spunbond-Meltblown-Meltblown-Spunbond) material is superior to SMS (Spunbond-Meltblown-Spunbond) for disposable surgical gowns due to several key advantages. The additional melt-blown layer in SMMS provides enhanced filtration efficiency and barrier protection against fluids and microorganisms. SMMS offers improved uniformity, higher performance levels (suitable for ANSI/AAMI Level 2 gowns and above), and a better balance between thickness, fluid protection, and breathability. It’s particularly well-suited for moderate-risk procedures involving moderate amounts of body fluids. SMMS surgical gowns typically have higher hydrostatic pressure in key areas, indicating better fluid resistance. Their versatility allows for use in gowns ranging from Level 2 to Level 4, depending on specific construction and treatments. While both materials are used in surgical gowns, SMMS is preferred for higher-risk medical procedures requiring greater barrier protection.

Polypropylene (PP)

Non-woven fabrics are created using a variety of processes that bond fibers together without weaving or knitting. Often, these fibers are derived from polypropylene, a thermoplastic polymer known for its durability and resistance to fluids. This material is highly regarded for its balance of strength and softness, ensuring comfort and protection.

By utilizing non-woven polypropylene as the base material, disposable surgical gowns can offer an effective barrier against contaminants while remaining lightweight and breathable. This makes them indispensable in maintaining sterile environments in surgical settings.

Polyethylene (PE)

Disposable surgical gowns often feature a water-resistant coating. This coating is typically applied to polypropylene (PP) or spunbond-meltblown-spunbond (SMS) materials. Such a coating ensures that the gowns offer robust protection against liquids, which is crucial in maintaining a sterile environment.

Not only are these gowns water-resistant, but they are also designed to be durable. This durability means they can withstand the rigors of surgical procedures, providing consistent protection throughout their use. The combination of water resistance and durability makes PE coated disposable surgical gowns an essential component in medical settings, ensuring safety and hygiene for both patients and healthcare professionals.

Spunlace

Disposable surgical gowns made of spunlace nonwoven fabric offer numerous advantages for medical applications. Key features include softness and comfort for extended wear, excellent absorbency for fluid management, and breathability to reduce heat buildup. The fabric is durable, low-linting, and biocompatible, making it ideal for maintaining sterile environments and suitable for sensitive skin.

It can be treated for enhanced fluid resistance and customized with antibacterial properties or specific fiber blends. Spunlace fabric is also environmentally friendly when made from biodegradable materials. The production process is efficient and cost-effective, not requiring binders or adhesives. These characteristics make spunlace nonwoven fabric an excellent choice for disposable surgical gowns, combining comfort, protection, and practicality for healthcare professionals in surgical settings.

Fabric Weight and Additional Treatments

The fabric weight used in these gowns typically ranges from 35 to 55 g/m². Heavier fabrics generally offer more protection, making them suitable for high-risk procedures. Furthermore, some gowns may have additional treatments or coatings, such as fluid-resistant finishes, to further boost their protective properties.(IOP Science)

In essence, disposable surgical gowns are designed with a blend of fibers and materials to ensure they are both protective and comfortable. This meticulous design helps healthcare workers stay safe without compromising on comfort.

Key Benefits of Disposable Surgical Gown Materials

Barrier Protection

The primary concern for disposable surgical gowns is barrier protection. These gowns are meticulously designed to shield healthcare workers from fluids and pathogens. Non-woven fabrics like polypropylene create an impermeable barrier that ensures no blood or bodily fluids can penetrate, maintaining a sterile environment and preventing infections. Effective barrier protection can reduce the risk of contamination by 60% (PMID: 2039364).

Comfort and Breathability

Comfort and breathability are essential for healthcare professionals who wear these gowns for hours. Disposable surgical gowns are crafted from lightweight, breathable materials that allow air to circulate, preventing overheating and discomfort. This breathability enhances performance and focus, reducing fatigue and increasing productivity. Imagine performing a delicate surgery while feeling suffocated – breathability is not just a luxury, but a necessity.

Durability and Strength

Despite being disposable, these gowns are incredibly durable and resistant to wear and tear. Advanced manufacturing techniques ensure that the gowns maintain their integrity even under rigorous conditions. This durability is vital for ensuring continuous protection throughout a medical procedure. The materials used are designed to withstand the rigors of the healthcare environment, ensuring that the gown doesn’t rip or tear easily. This not only provides peace of mind but also saves time and resources by reducing the need for frequent gown changes.

By combining robust barrier protection, unparalleled comfort, and exceptional durability, disposable surgical gowns are indispensable in modern healthcare settings.

Environmental Considerations

Disposability and Single-Use Benefits

Why are disposable surgical gowns the go-to choice for many healthcare settings? Well, it’s all about convenience and safety. Unlike reusable gowns, disposable options eliminate the need for laundry, saving time and resources. Imagine a busy hospital where every second counts. Wouldn’t you want a fresh, sterile gown every time? That’s exactly what disposable gowns offer. They’re designed to be used once and then tossed away, which means there’s zero risk of cross-contamination. Plus, they’re lightweight and comfortable, making them ideal for long shifts.

Sustainability Efforts

But what about the environment? Good news! The industry is making strides in sustainability. Many manufacturers are now using eco-friendly materials and biodegradable components. Some companies are even exploring recycling programs to reduce waste. While disposable gowns aren’t perfect, ongoing innovations are helping to minimize their environmental footprint. It’s a small step, but every little bit helps, right?

Disposable surgical gowns are made primarily from non-woven fabrics like polypropylene and polyethylene. Polypropylene is durable, moisture-resistant, and lightweight, reducing hospital-acquired infection risks by up to 30%. Polyethylene enhances liquid protection, often laminated onto polypropylene for better barrier performance. SMS (spunbond-meltblown-spunbond) fabric is a superior choice, combining strength and excellent bacterial penetration protection. Gown design and manufacturing quality, such as reinforced sleeves and seams, also impact protection and durability. Selecting the right materials ensures the safety and comfort of healthcare professionals. For custom disposable surgical gown requests, contact Morntrip – a leading manufacturer of medical gowns in China, for the right solutions.